FlexXray stands out in the food safety space for a number of reasons, and our ability to handle expansive, in-depth projects is just one of them. This is one of my favorite stories to tell because it highlights how our speed, agility and accuracy all come together to save the day for our customers.

When this particular customer’s in-line X-ray machine failed, they realized that two days’ worth of product — in this case, boxes of cereal bars — needed to be audited for verification that the product was safe for commerce. FlexXray can do that, no problem.

But the story would be too short if it ended there! As soon as we began inspection, their initial problem grew in two different ways:

- A new X-ray machine would take 6 to 8 weeks to arrive and be installed.

- Around truckload #10, we began to find rocks in the product—something an in-line machine wouldn’t have been able to catch in the first place.

Where do we go from here?

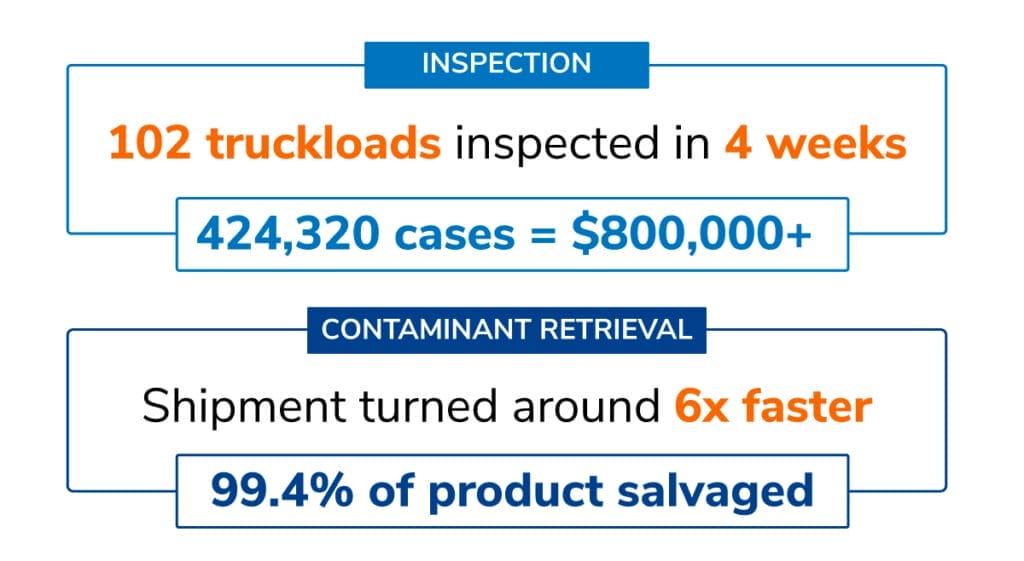

First, FlexXray helped during the time period between their in-line machine breaking down and their new machine arriving. In total, we inspected 102 truckloads of product (424,320 cases worth more than $800,000) over a 4-week period. However, it’s not in our nature to stop there—we don’t take the title of “full-service provider” lightly.

Immediately after we discovered the foreign material contaminants, we reached out to our customer to determine how they wanted to proceed. When they opted for contaminant retrieval, we got right to work, turning around what would typically be a 48-72 hour process in just 12 hours. Our team provided contaminant samples to help them determine what type of rock was in their product and where it might have come from. They were able to isolate the problem to an ingredient from one of their suppliers, who quickly became a FlexXray customer as well.

Our inspection and retrieval services allowed this customer to salvage a majority of their product (99.4%) and come to an agreement with their supplier that aims to prevent similar issues in the future.

A few quick notes on why this project was so successful for both FlexXray and this customer:

- Decision-makers were involved up front, allowing us to move forward much faster when a secondary issue arose.

- We have technology others don’t, enabling us to inspect at case level (through exterior cardboard and interior foil) and still find small contaminants.

- Our team worked overtime to get the job done as quickly and accurately as possible.

What this customer initially thought was a simple good-faith audit turned into a lesson in supplier verification and ongoing QA control processes, specifically related to foreign material contamination.

Would you believe me if I told you we could do it even faster now? Since this happened, we’ve upgraded even more—better machines and more facilities allow us to work faster and at greater depths than ever before. If you want to know more, just reach out—I’d love to tell you!

When you don’t know where to start, FlexXray does.