Food waste is a major concern both globally and in the United States. According to the USDA, food waste is estimated at 30-40% of the food supply, with around 10% of that waste generated in manufacturing. This is a system-wide problem with no one solution. In the manufacturing space, food waste is generated at multiple points, from failure to meet standards at the farm level to processing issues at the manufacturing level. The USDA, FDA and EPA have engaged with ReFed, a non-profit working to end food loss and waste, that has set a goal to reduce food waste in the U.S. by fifty percent by 2030.

As a manufacturer, food that ends up in a landfill impacts your bottom line. In many instances, this loss can be avoided when the issue is connected to foreign material contamination issues. Furthermore, as organizations adopt internal ESG (Environment, Social and Governance) standards, food waste harms progress toward these goals.

Fortunately, this is an area where FlexXray can work with you to help you take an active approach to reduce food waste in America by identifying contaminated food within your bracketed product. Our approach allows you to salvage uncontaminated product, reducing your food waste footprint.

If you watched the Super Bowl this year, you might have noticed that Hellmann’s has used their platform to put an interesting spin on food waste:

Again, food waste is a system-wide issue, and this commercial is part of a broader campaign from Hellmann’s to position their brand as a leader in the fight against the known and growing problem of food waste at the consumer level. They go further, offering solutions to the problem of waste through innovative applications. We applaud Unilever for taking a creative, solution-based approach with the Hellmann’s brand.

At FlexXray, we do the same thing every day. FlexXray uses a creative, solution-based approach that can help make a significant impact at the production and distribution levels.

If you suspect—or know—that your food product is contaminated with foreign material following production, you’ve historically had one of two choices to make: (1) rework the product and find contamination using your in-house systems and processes or (2) take your food to a landfill. The latter of these approaches (according to the Food Recovery Hierarchy) is the least preferred method for dealing with food waste.

These options are costly and wasteful, but FlexXray can offer a third option—send us your product. We use custom processes and x-ray technologies to find and retrieve foreign material contamination so you can recover safe product instead of contributing to food waste.

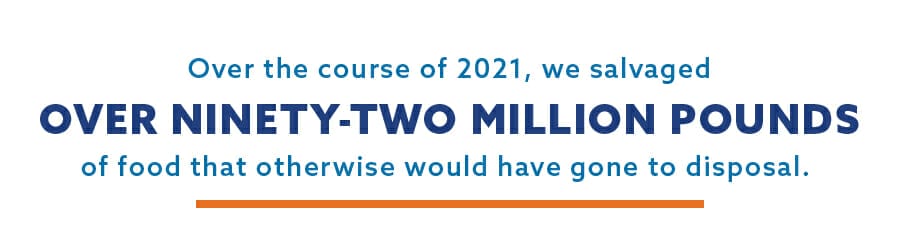

In fact, we inspected over 95 million pounds of food in all, and we were able to salvage 97.4% of the product we inspected. That’s a serious hit to food waste.

Foreign material contamination is a small piece of the broader problem of food waste in our country, but it’s an issue that FlexXray knows how to solve. If you want to show your commitment to your environmental and social responsibility goals and improve your bottom line, call FlexXray when you have issues with foreign material contamination.