The final quarter of the year is quickly approaching, and with it come significant national holidays—in fact, many consumers are already getting into the spirit(s). Are you prepared for the holiday season? Don’t let a product hold due to foreign material contamination prevent you from meeting customer demands.

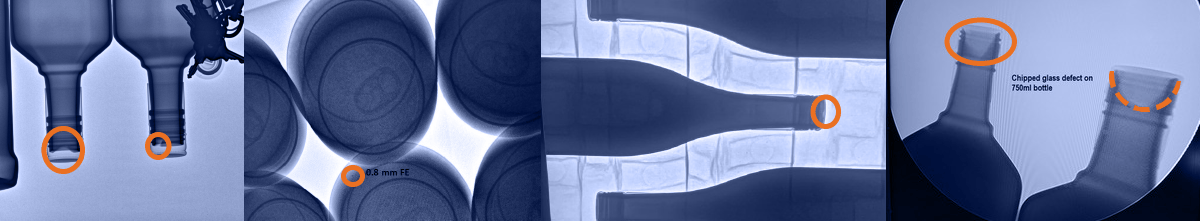

No industry is exempt from foreign material contamination issues, wine and spirits included. With that said, foreign material isn’t your only concern—more unique to your industry, but highly relevant, are concerns including glass chips, sealing issues, can and bottle defects and more. If you don’t have the time and/or labor to inspect your product for those issues, FlexXray can help.

We’ve inspected truckloads of product on hold and found defects and contaminants manufacturers never suspected (not to mention those they did).

Picture your operations at the plant level. Think about the number of different materials required to create your finished product. Consider the added potential for human or machine error within a production run. If you aren’t yet wary of the potential for packaging defects and foreign material contamination, reflect on these real-life examples:

- Broken glass in sealed bottles

- Double-lidded cans

- Cork defects affecting both product useability and shelf life

- Sediment at the bottom of product, including stems and seeds

Here’s the bottom line: our customized X-ray food inspection service can locate contaminants of all types, as small as 0.8 mm. Plus, our skilled team of experts can inspect product by hand to catch defects machines can’t. Don’t risk sending a contaminated, defective product to market. Sip back, relax and let FlexXray find what other equipment may miss.

FlexXray’s quality assurance services extend into the wine and spirits industry. If you have product on hold, send it to us for inspection today! We’re here when you need us—and when you think you don’t.