Manufacturers, if sending a top-notch product to market is your goal, quality control must fuel your operation. You have critical control points woven throughout your HACCP plan, but if your QA measures end there, you’re missing something. Countless contaminants can end up in your product along a production run, from bone to metal to glass to plastics. The good news: FlexXray offers X-ray inspection services that can find (and retrieve) them all.

Foreign material contamination is a prevalent risk, and if you aren’t planning accordingly, it’ll quickly turn into an issue that can impact your ability to meet customer deadlines and production quotas, place a strain on current raw ingredients supply, and many other issues. We’re on a mission to reduce the impact of foreign material contamination on your bottom line, and our X-ray inspection services can do it. Think of FlexXray as your full-service station, ready when you need us.

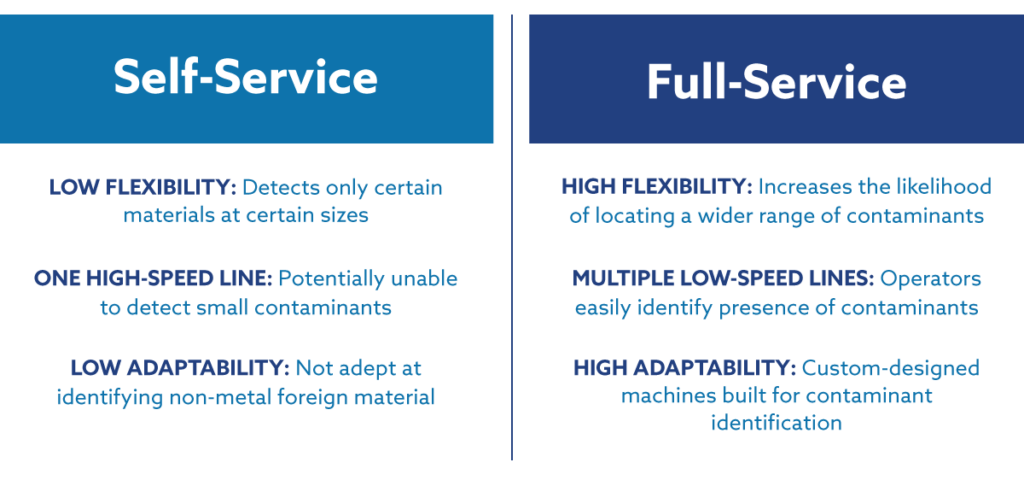

The bottom line is that in comparison to in-line technology, FlexXray’s X-ray inspection services can be more cost-effective, bring a higher return on investment, provide extreme accuracy, consistency, and reliability, and make for a smoother contaminant retrieval process following identification.

If you have concerns about your in-line technology’s ability to find ALL foreign material in your product, call FlexXray today. We’ll set up a personal tour of our facility for you and your team, showing you how our X-ray inspection services work. If you have product on hold right now, contact us and we’ll inspect a sample for free, with no obligations.