Food recalls due to biological contamination have been in the news for years. In 2018, salmonella was the top cause, with the Center for Disease Control (CDC) reporting eight food-related outbreaks between January and July. One of those outbreaks affected consumers across seven states, resulting in numerous hospitalizations. This leaves consumers wondering: Is biological food contamination becoming more common?

It’s true that we’re hearing more about these events. However, it’s not necessarily because they’re happening more frequently. The reality is that consumers now have easier, faster access to the news than ever before. Plus, regulating agencies such as the CDC, Food and Drug Administration (FDA), and the USDA’s Food and Safety Inspection Service (FSIS) now have better technology to identify and track outbreaks.

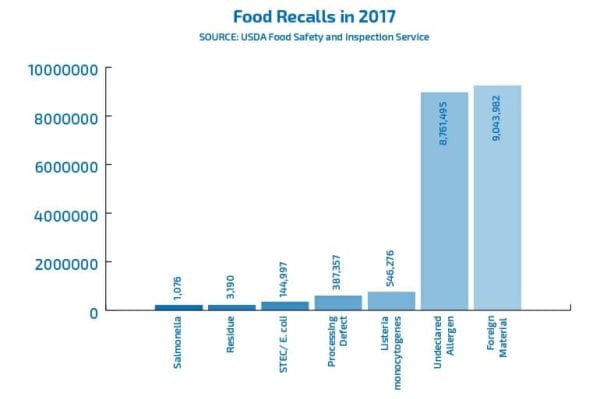

Cases involving physical contamination of food are less common in headlines—only a few cases made the news in the last year. The relatively sparse reporting about this topic would suggest that it’s much less common than contamination from biological sources. Data from the USDA proves that assumption wrong.

How Frequently Physical Contaminants Appear in Food

In 2017, the USDA reported that more than 9 million pounds of food were recalled due to the presence of an extraneous material. By comparison, 546,276 pounds of food were recalled due to listeria and 1,076 pounds of recalled food were attributed to salmonella.

Additionally, a five-year study by Stericycle released earlier this year found that foreign materials are the leading cause of food recalls. Of foods contaminated by physical matter, beef was the most recalled food, and heavy metals were the most common form of contamination. However, even though there are more incidents of physical contamination, they are less widely reported, leading many to believe that biological contamination is a greater threat.

Physical contaminants can have serious, far-reaching effects both on consumers and food manufacturers. However, since biological contamination can lead to outbreaks that spread from person to person after consumption of a tainted food product, it can quickly become a public threat — one that grabs the attention of the news and social media.

Physical Contamination in Food: Methods of Prevention

Preventing physical contamination of food and beverage products begins with recognizing the many hazards in the manufacturing process. Contaminants can enter the food supply at any point, from the field during harvest to the final stage of packaging.

Sources of physical contaminants in food can include pieces of broken equipment that land in the product, employees losing objects like earrings and pens, or rocks and wood pallets where the food originated.

Today, it would seem that with all the measures in place to detect contaminants, the incidence of foreign objects found in food would be declining. However, according to the aforementioned Stericycle report, recalls have actually increased by 33% in the past five years.

This doesn’t have to be the case. Below are three measures food production facilities can take to ensure their products remain free from foreign materials.

1: Implement Control Processes

Whether you choose to or are required to follow multiple systems such as HACCP, Food Defense, or Food Safety, it’s important to avoid treating these systems like boxes to check off. Ensure they’re thorough and understood by everyone in your facility.

Following the seven principles for HACCP developed by the National Advisory Committee on Microbiological Criteria for Foods can help you establish effective procedures and put a system in place so you’ll know exactly what to do in the event that contaminants are discovered.

2: Create a Culture of Food Safety

Creating a culture of food safety doesn’t just happen; it takes planning and buy-in from the top down. It means committing to the safety of your product and the efficiency of your procedures, then implementing measures to make sure that employees have the education and tools needed to uphold those principles.

Provide reinforcement and training to ensure that these guidelines are followed. When food safety is a top priority for your company, everyone benefits.

3: Utilize Advanced X-Ray Inspection Technology

The use of advanced X-ray technology is the most effective way to ensure that your food product is free of physical contaminants. While tools like metal detectors, magnets and filters can be useful for some products, X-ray inspection provides an advanced level of detection.

If you’re already utilizing X-ray technology on the production line, you know that it can help identify physical contaminants. However, the speed of the line may prevent you from taking a closer look at a product hold, which is where a third-party X-ray food inspection service can provide the resources you need.

Leveraging the resources of a third-party service dedicated to locating and identifying contaminants can save producers the cost of disposing of a bracketed product run while at the same time ensuring that contaminated product doesn’t reach consumers.

As food recalls continue to increase and consumers become more aware of them, it’s important for food manufacturers to protect their brand and reputation. Avoiding a food recall by eliminating the possibility of physical contamination is one of the best investments you can make in your company’s future.

Leave a Reply

You must be logged in to post a comment.