X-Ray Food Inspection Protects Your Company

A COMPLETE GUIDE

Food manufacturers use X-ray food inspection to avert foreign material contamination issues that can result in:

- Recalls

- Lost business

- Loss of brand/company confidence

- Out-of-stock situations

- Lawsuits

Foreign material contamination is a growing problem and a key risk that you can mitigate with the right tools and support. When you need help, consider FlexXray an extension of your quality, safety and operations teams. With our medical-grade X-ray technology and expertise in rework and recovery, we can step in to assist you when your own systems indicate that there’s a problem.

It’s important to understand evolving, modern X-ray technology and how it can work to protect your customers, products, business and reputation. This guide will show you how—use it yourself, and share it with your team.

Kye Luker

Chief Product Officer, FlexXray

The Growing Problem of Foreign Material in Food

Although bacterial or chemical food contamination grabs most of the headlines, the problem of foreign material contamination is getting greater attention and remains a significant issue for food manufacturers.

In 2020, USDA’s Food Safety and Inspection Service reported that 2.9 percent of the total food recalled that year was due to foreign material. In 2021, there was a decrease of 27 percent in total food recalls; the FDA and USDA attribute this decrease to actual incidents going unreported.

Your goal is to prevent contaminated food from reaching consumers with minimal disruption—and the best way to do that is through X-ray inspection.

Are more foreign materials making their way into our food supply, or is it simply a case of less tolerance by regulators of contamination? The bigger question may be: Why does this remain a problem in a world where we have so many opportunities for detection?

First, how does food contamination occur? Foreign material contamination can come from:

- Internal equipment failures, such as machine parts that rub or break

- Human error during production

- Suppliers or vendors that provide you with contaminated foods

- Intentional sabotage from disgruntled employees

More than 387,000 pounds of food were recalled in 2020 as the direct result of foreign material being present. Recalls are costly, inefficient and devastating to a brand or company image—here’s proof. Any food manufacturer that faces a contamination issue must resolve the problem quickly and with as little production disruption as possible.

The Evolution of Food Safety Technology

As more processed foods have entered our world, so have greater risks for contamination. Contaminants enter our food supply in many ways:

- Rocks and debris at the agricultural level

- Wires for sifting, sorting or cutting

- Metal flakes from blades, grinders, blenders or extruders

- Nuts, bolts, washers or filler nozzles

- Rubber and plastics from o-rings, gaskets, parts and tools

- Ceramic pump seals

- Glass from packaging materials or instrument devices

The need for food safety technologies is critical.

X-ray detection is a viable and practical form of threat detection for food manufacturers. As technology improves and costs drop, food manufacturers have more choices in their food safety options. X-ray inspection as an offline service provides the ideal complement to inline inspection capabilities.

Inline systems are a good first step for detection. When they find contamination, the next step is a more sophisticated offline X-ray service. Because offline systems like FlexXray run at a slower rate with varying power supply, they can find even tinier foreign materials—down to 0.8 mm and smaller. As technology continues to advance, so will innovations in food inspection—and so will the level of food safety enjoyed by consumers and manufacturers alike.

At FlexXray, we use a custom-built system that leverages medical-grade technology that inline flat panel detectors can’t compete with.

Pros and Cons of Foreign Material Detection Systems

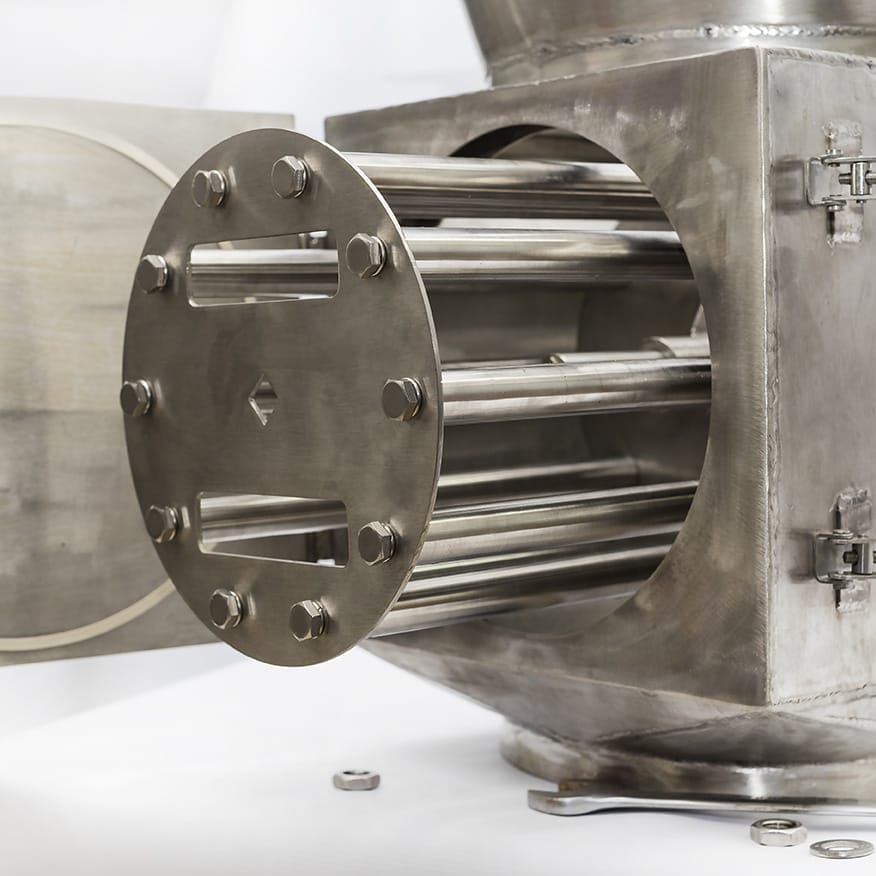

Magnetic Separators

This is the simplest method for keeping unwanted metallic materials out of your inventory. Magnetic separators gather ferrous objects, those that contain iron and some stainless steel.

PROS:

- Designed for ease and efficiency

- Good for large production runs

- Can use rare earth magnets to support stainless steel recovery

CONS:

- Cannot find nonferrous metallic (aluminum, brass) or nonmetallic items

- Can become a source of foreign material contamination themselves

Metal Detectors

Metal detectors use an electromagnetic field from coils to locate metal contaminants in food as it passes through the manufacturing line. Several types of metal detectors can be used in different types of food manufacturing environments.

PROS:

- Widely used and readily available

- Easily integrated into production line settings

- Better than any other method for aluminum detection

CONS:

- Cannot identify non-metallic contaminants

- Subject to various factors such as moisture, salt, sugar or electrical interference from other devices

- Not usable where metal packaging is used

X-Ray Inspection Machines

These inspection machines use X-rays and an imaging system to locate foreign contaminants. They pass low-energy rays into the product as it passes through a detector and can detect dense foreign objects by the way the object absorbs or deflects the X-ray energy.

PROS:

- Better than a metal detector for most manufacturing settings

- Capable of finding non-metallic items like stone, bone, ceramic and glass

CONS:

- While the most cost-effective solution overall, upfront costs are higher than metal detectors or magnets

- In-line calibration is often not user-friendly and can result in false reject issues if not done properly

- Creates a need for radiation safety compliance in the facility

Manufacturers have many options for internal detection. Choosing the best one for your situation is key. When those systems are not robust enough, have gaps in detection/rejection, and/or if they are not set up to provide specialized rework of the product placed on hold, third-party services can step in for you.

Understanding X-Ray Food Inspection

X-ray food inspection uses advanced X-ray technology to detect contaminants. Like every other type of X-ray, it uses light waves to “see” beyond what our eyes can see. In this case, that means looking inside food products and packaging. X-rays base their reading on the density of the product, and each time those rays penetrate a product, some of the energy of the ray is lost.

When a foreign material is present, it loses even more energy. Sensors take images of this reading, producing an X-ray or picture of what’s inside the food.

Once an X-ray shows what contaminant is present and where it’s located, you have the power to correct the situation.

How X-Ray Food Inspection Machines Work—Safety Considerations

X-ray inspection machines detect many types of physical contaminants and are completely safe. While metal is a major source of contamination in food, it’s not the only quality control hazard. Depending on the type of food, where it’s grown and what manufacturing process it grows through, food can become contaminated by rubber, bone, wood, stone, plastic, glass and more. Metal detectors can only detect metal, which means food contaminated with other hazards could be distributed to consumers, putting both customers and your company at risk.

These machines have become so sophisticated that they find dense matter that doesn’t belong, and they can distinguish between contaminants and anomalies like metal retaining clips or packaging. They can handle a variety of formats, from cans and bottles to meat products and bulk food.

Because it offers such an extreme level of efficiency, accuracy and safety, many manufacturers now rely on X-ray inspection to ensure that products are not only meeting food safety guidelines and the standards of retailers, but are meeting the high standards of their own brand every time.

The food spends very little time under an X-ray beam, which means it receives a minuscule dose of radiation during that time. Today’s equipment is more efficient than ever and can operate at as much as 70 percent lower wattage than the systems used a decade ago.

The U.S. Food and Drug Administration confirms that X-ray inspection doesn’t cause adverse effects to the food supply, nor does it change the taste, flavor or nutritional value of the inspected product. According to a study conducted by the World Health Organization, food can be exposed to more than 600 million X-ray scans without compromising any of its quality or safety.

Inline Equipment vs. FlexXray X-ray Food Inspection

Manufacturers often ask “If I have an inline inspection machine at my plant, why should I use third-party X-ray inspection?” Both inline systems and FlexXray’s systems inspect food for contaminants; however, they don’t have the same capabilities.

Inline equipment is essential in monitoring food to make sure that FSMA regulations are met. These machines may flag product runs that show the presence of a foreign material, which lets you handle the next steps rather than risk putting contaminated product on the shelves.

Yet, even with the best inline technology, you will still have affected product that you need to place on hold after investigating the root cause. Your facility is built and staffed to make product, and stopping to re-inspect or rework product is a significant loss of time, resources and money. Because the line moves quickly, your system may indicate a contamination problem, but it can’t pinpoint exactly where that contaminant is or identify the issue. You’ll incur additional costs to rerun the bracketed product at a slower pace. If you dispose of the product, you potentially throw away more than necessary. Plus, proper disposal is costly in its own right.

You can’t afford to have your lines slowed down for quality control practices, but a third-party service like FlexXray can pick up where your equipment leaves off. We have the proper time, staffing and technology to find the “needle in a haystack,” help you recover quickly and maintain your focus on the next production run. Because we document every step to your specifications, you’ll have complete traceability and be prepared to pinpoint how the contamination occurred.

Contamination is an unfortunate inevitability in food manufacturing. When it does occur, you need a trusted ally, like FlexXray, who can step in quickly to resolve your issue. Having an unbiased, trained third-party resource provides peace of mind to you, downstream customers and, eventually, consumers.

PRODUCT ON HOLD FOR FOREIGN MATERIAL CONTAMINATION?

Cost Options and Comparisons

A third-party X-ray inspection service is a fraction of the cost of a food recall, which averages nearly $10 million per incident. In addition to up-front expenses, the consequences of damaging your brand and reputation can go much deeper. Although there are other options, the cost of inspection is much less than any other solution.

Consider the options:

Dispose of the full production run

- Doubles the cost of a production run (including ingredients, packaging, labor)

- Slotting fees and/or out-of-stock penalties from retailers

- Disposal costs

- Landfill waste

Shut down production for re-inspection and rework

- Labor and overtime costs

- May still have to absorb the cost of another option

Risk it and ship the product to retailers

- Potential cost to brand and company reputation

- Potential recall costs

- Potential third-party inspection costs

- Potential litigation costs

Use third-party X-ray inspection with FlexXray

- Shipping costs to the FlexXray facility

- Cost of inspection

A third-party X-ray inspection and contaminant removal service is often the most cost-effective and lowest-risk option. It ensures the specific contaminant is located and removed at minimum cost to the manufacturer while keeping a substantial amount of the product out of landfills and in commerce.

How Does FlexXray Food Inspection Work?

To avoid foreign material issues, you need a plan that covers every possible threat to food safety within your facility. It’s equally important to have an X-ray inspection partner in place that can detect foreign materials that might contaminate your food. The FlexXray inspection process can identify many foreign materials and help you take steps to resolve the issue. In today’s world, it’s important to have a trusted partner that can handle food contamination issues with your product quickly and discreetly.

X-Ray Inspection

We understand that finding foreign contaminants can cause a big headache for you. We’re here to make it simple while saving you time and money. At FlexXray, we pride ourselves on being that trusted food safety partner to more than 1,200 food manufacturing facilities throughout North America.

The Future of X-Ray Food Inspection

As threats to food safety increase, manufacturers need X-ray inspection to protect their brand reputation and the future of their business. X-ray inspection is the ideal solution for today’s increasingly complex food industry. With such things as multi-texture foods and the increasing presence of superfruits in certain foods, the X-ray industry is working to better identify such ingredients to prevent false identification of foreign materials. As the industry becomes more sophisticated, so do the tools required to safeguard it.

Compliance will always be a concern for food producers, and as the regulations surrounding food and drug safety continue to tighten, traceability throughout the stages of your food’s life cycle is increasingly important. Full compliance requires complete traceability, and the ability to implement X-ray inspection is the most effective tool to ensure your company is producing not just the best product it can, but also the safest.

X-ray inspection is the ideal solution for today’s increasingly complex food industry. Manufacturers who use FlexXray for their X-ray inspection needs have greater confidence in the

safety of their product.

About FlexXray

When your inline systems notify you of an issue, your next call should be to FlexXray.

FlexXray is North America’s leading foreign material inspection company and your partner in food safety. Our custom-built direct X-ray technology detects issues before products go to market, saving companies like yours millions of dollars each year. Based in Arlington, Texas, we serve the largest food companies across the United States and Canada. We offer inspection solutions at our FDA and USDA-registered and temperature-controlled facilities.