Food inspection processes continue to become more sophisticated, creating a safer food environment and providing peace of mind both for food manufacturers and for consumers. Today, inline processes have evolved to include metal detectors and X-ray inspection. While that has greatly enhanced food safety and inspections, inline machines have their limitations.

For instance, inline machines may fail to detect the presence of physical contaminants, such as wood, glass, metal, rubber, plastic, stone and more.

And while metal detectors can be effective in identifying metal particles, they won’t help if the product is contaminated with some other type of foreign particle — nor are they useful when inspecting products in aluminum-coated packing materials. Screens, inline magnets and filter socks can all help capture physical contaminants, but aren’t suitable for all types of food products or all food manufacturing environments.

Although inline X-ray machines can find fragments and contaminants of metal within food product, these machines must also keep up with the speed of manufacturing. As such, they are often not consistently detecting objects below 3 to 5mm in size; particularly when it comes to the other types of physical contaminants mentioned above.

That’s when food companies can use a third-party inspection process to better determine what kind of contamination has occurred and how best to approach it.

A Closer Look at X-ray Inspections

“Comparing the technology from standard inline machines and what we can do at FlexXray is really comparing apples and oranges,” says Kye Luker, Chief Product Officer for FlexXray.

“Every food company today needs a good inline inspection program, and what’s best for them is going to vary from one company to the next.”

But part of that inspection program should also include a strategy of what to do when a potential contaminant is discovered.

“When physical hazards trigger an incident, the first response shouldn’t be to bracket the product and throw it away,” he says. “That’s where we come in.”

FlexXray’s leading-edge technology, which is dedicated specifically to locating and identifying physical contaminants in food, requires more space than the technology used in a food plant. It also is operated at a much slower pace. While not viable for a fast-moving food production environment, it provides the perfect solution for foods that have been flagged as containing physical hazards.

Slowing Down the X-ray Process (Without Slowing Down Production)

Luker explains that while many inline inspection processes now use X-ray machines, there are differences between what’s available for in-house inspection and what is possible through a third-party inspection service. It all comes down to the size and capability of the equipment — and what’s feasible in each setting.

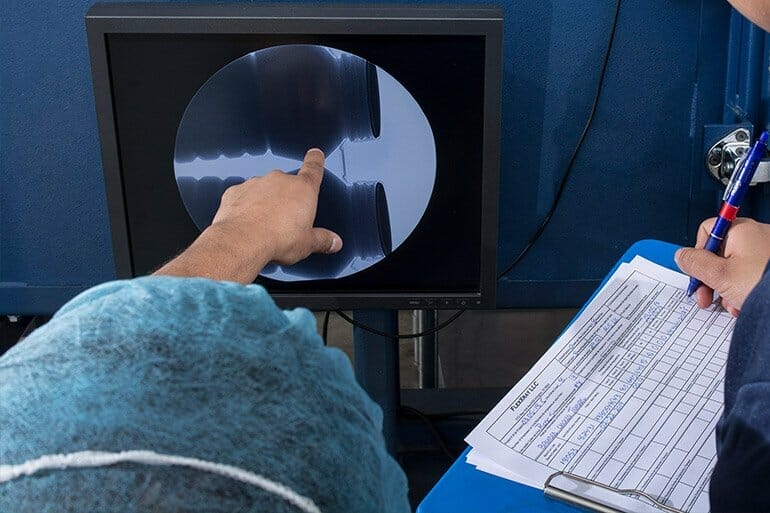

While inline inspections use flat panel detectors (similar to what the TSA uses for airline baggage screening) FlexXray machines use custom, medical-grade technology. When a contaminant is detected, this technology allows the person monitoring the line to zoom in and enlarge the area for closer inspection.

“There’s a significant difference between the size of the two types of X-ray processes,” Luker says, explaining that the small-profile, flat panel technology fits easily into the stainless steel cabinet of an inline inspection machine, making it ideal for production lines. “On the flip side, the FlexXray cabinet X-ray platform is much larger, and its system, due to the medical grade nature, is vulnerable to dirt and movement. So it wouldn’t work well in the environments where a flat panel is used.”

When an inline X-ray inspection machine detects foreign particles as designed, there is still an investigation into the source and bracketing of product that occurs. Thousands of pounds can still be quarantined and put on hold. At this point, manufacturers can and should send their product to FlexXray. FlexXray’s technology can then find the remaining contaminants an inline system is not capable of detecting and can help avoid added costs of rework, re-inspection, or re-production of the bracketed product.

While food manufacturers may run 10,000 pounds of product in an hour, FlexXray’s machines are designed to run at much slower speeds. When the line technician notices shading or a change in density, he or she can stop the line, zoom in to further identify whether or not it is a foreign material, and remove the product from the line.

Safely Salvaging the Rest of the Product

Once a physical contaminant is found and that product is removed from the line for safe and proper disposal, the rest of the production run is inspected to ensure there are no other contaminants. Then the safe, inspected food can re-enter the supply chain and be shipped to wholesalers or customers.

“There are differences in what each of these machines can do,” Luker says. “A flat panel detector in an inline machine is never going to find a 1mm piece of plastic or other non-metallic foreign objects; the algorithms just aren’t there and the machine is moving too fast.”

Instead, what it can do is flag the product as having a possible contaminant, allowing the manufacturer to choose the next steps. Sending it to FlexXray for closer inspection allows food producers to recover the non-contaminated product and also can help identify where the contamination originated, such as from a supplier or at the manufacturing plant.

“Inline X-ray machines are important, but they can’t do everything,” Luker says. “Our technology allows us to detect down to 0.8 mm and smaller, but more importantly, we can find the types of foreign material that in-line systems simply can rarely detect: stone, plastic, rubber, glass, bone, etc… So when customers know they have a problem, we know that we’re going to be able to find it and help them recover.”

Leave a Reply

You must be logged in to post a comment.