Foreign material contamination occurs when foreign materials or foreign objects inadvertently end up in products during manufacturing or processing. In the food industry, this type of contamination can pose serious risks to consumer health and damage a company’s reputation. Understanding what constitutes a foreign contaminant, how it occurs, and the steps to prevent it is crucial for maintaining product integrity and ensuring consumer safety.

Foreign Material Meaning: Defining the Problem

Foreign material refers to any unwanted substance or object introduced into a product that is not part of its intended composition. Examples of foreign materials in food include:

- Metal fragments

- Glass shards

- Plastic pieces

- Wood splinters

- Bone or shells in processed products

These contaminants can enter the supply chain at various points, from raw material sourcing to packaging and distribution.

FAQs About Foreign Material Contamination

A foreign contaminant is any unwanted object or substance introduced into a product, such as metal fragments, glass shards, or plastic pieces.

In food safety, foreign material refers to non-food items or contaminants that compromise the quality and safety of the product.

Foreign material contamination can be detected using advanced inspection technologies like X-ray inspection and metal detection systems.

Contamination can lead to physical injuries, illnesses, or allergic reactions, posing significant health risks to consumers.

To learn more, watch this webinar!

How Does Foreign Material Contamination Happen?

Foreign material contamination is often caused by:

Equipment wear and tear: Broken machinery parts, such as metal or plastic fragments, can fall into products during processing.

Human error: Improper handling, accidental dropping of tools, or poor cleaning practices can introduce foreign objects into the production line.

Supplier issues: Raw materials may already contain contaminants if not properly inspected before delivery.

Packaging failures: Faulty packaging materials or processes can lead to contamination.

Understanding these causes helps manufacturers implement strategies to reduce the risk of contamination.

Why Preventing Foreign Material Contamination Matters

The presence of foreign materials in food or other products can have serious consequences, including:

Health risks: Ingesting foreign objects can lead to injuries, choking, or illness.

Regulatory non-compliance: Contaminated products violate food safety standards and can result in fines or recalls.

Reputation damage: A single contamination incident can erode consumer trust and harm brand loyalty.

Preventing Contamination Caused by Foreign Objects

To minimize the risk of foreign material contamination, manufacturers should adopt robust prevention measures, including:

Inspection systems: Implement advanced detection technologies, such as X-ray inspection or metal detection, to identify and remove contaminants before products reach consumers.

Regular equipment maintenance: Routine inspections and repairs can prevent equipment-related contamination.

Stringent supplier audits: Ensuring suppliers meet high safety and quality standards reduces the likelihood of receiving contaminated raw materials.

Employee training: Educate staff on best practices for hygiene, equipment handling, and contamination prevention.

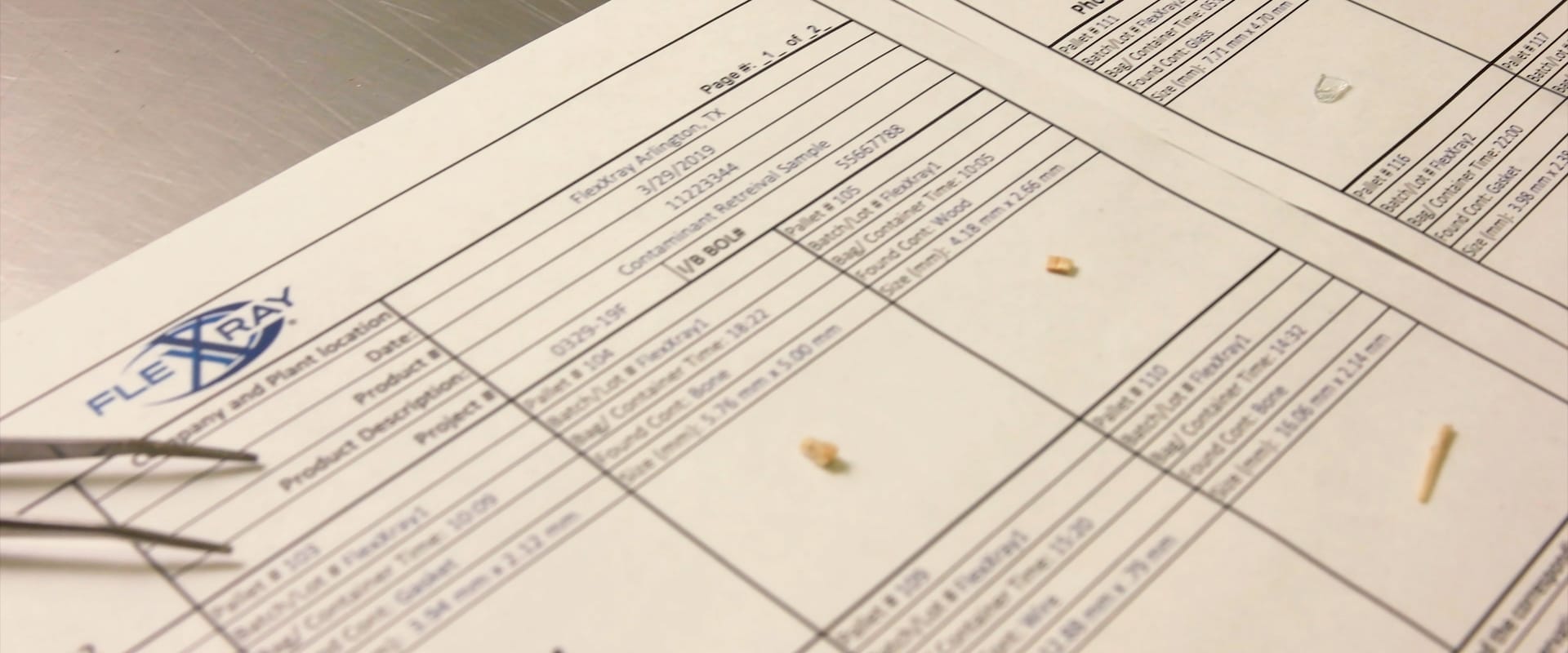

Foreign Material Detection and FlexXray’s Role

FlexXray specializes in the inspection and detection of foreign materials in food and other packaged goods. Using state-of-the-art X-ray technology, FlexXray can identify and remove contaminants with pinpoint accuracy, helping manufacturers recover products while maintaining safety and compliance.

Our services address contamination issues caused by:

- Metal

- Glass

- Plastic

- Rubber

- Stones

- Wood

- Bone

- Wire

By partnering with FlexXray, companies can mitigate risks, protect their reputation, and avoid costly recalls.

FlexXray is the trusted leader in foreign material inspection and contamination resolution. Our team works closely with manufacturers to ensure every product meets the highest safety standards. With industry-leading expertise and cutting-edge technology, FlexXray provides fast, reliable solutions for contamination issues, allowing companies to:

- Recover valuable products

- Maintain compliance

- Safeguard their reputation

Contact us today to learn more about how FlexXray can help protect your business from the risks of foreign material contamination.

Leave a Reply

You must be logged in to post a comment.