In the world of food manufacturing, even the smallest changes can have significant impacts. Recently, our customer faced a dilemma that many companies have: a change in shelf life for their premium frozen pet food. While the news from their lab’s analysis was excellent—a six-month extension to the product’s shelf life—the logistics of updating product labels inside 36,000 cases posed a formidable challenge.

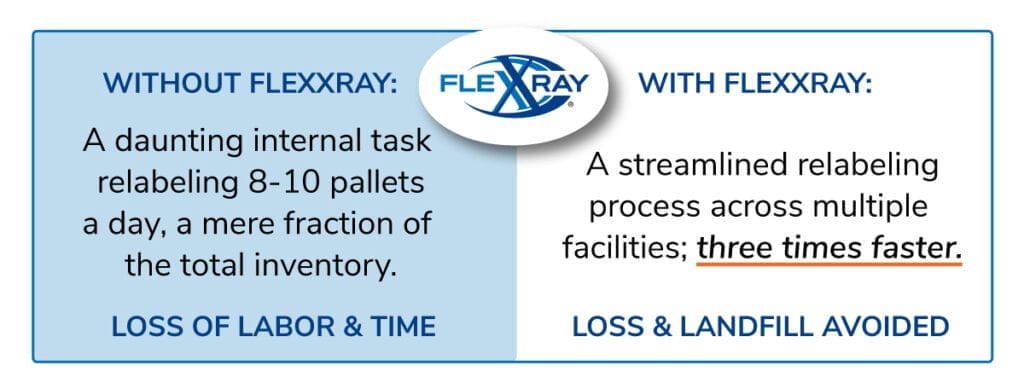

The customer initially embarked on the daunting task internally, dedicating entire shifts to completing just 8-10 pallets a day, a mere fraction of the total inventory. With 900 pallets requiring relabeling, it quickly became evident that their resources were limited to meet the deadline without risking product expiration.

Recognizing the urgency of the situation, the customer reached out to FlexXray. Upon assessment, we identified a critical need for swift and efficient action to prevent unnecessary delays and potential losses. Utilizing our expertise and state-of-the-art facilities, FlexXray proposed a comprehensive solution to streamline the relabeling process. Through initially conducting a time study and labor hours required, we were able to exceed expectations by completing twenty-six pallets daily—three times faster than the customer’s initial efforts.

Our multi-facility approach enabled us to tackle the monumental task of relabeling 35 truckloads, totaling about 750,000 new labels, in a matter of weeks rather than several months. Employing an assembly line-style process, our staff diligently opened cases, removed old labels, and applied new ones with efficiency. Moreover, we provided cold storage when needed, and detailed reports, including LOT numbers, and temperature checks, ensuring compliance with supply chain standards.

Our collaborative efforts not only expedited the relabeling process but also averted potential financial losses and landfills. The products were promptly delivered to retail shelves nationwide, and we helped our customers with a significant ROI while minimizing disruptions to their operations.

In conclusion, the successful outcome of this endeavor exemplifies the power of innovation and partnership in overcoming challenges within the food manufacturing industry. At FlexXray, we remain steadfast in our commitment to providing flexible solutions that exceed expectations and drive success for our valued customers.