Why CT Matters in Food Safety

Traditional X-ray inspection is powerful, but some contaminants and subtle product inconsistencies can still slip through. CT scanning gives you a 3D view inside your product, revealing foreign material and defects in ways standard X-ray cannot.

- Detect small or complex contaminants: wires, glass, stones, dense plastics, bone fragments

- Preserve product quality while protecting your brand

- Gain data-driven insights for FSQA and operational improvements

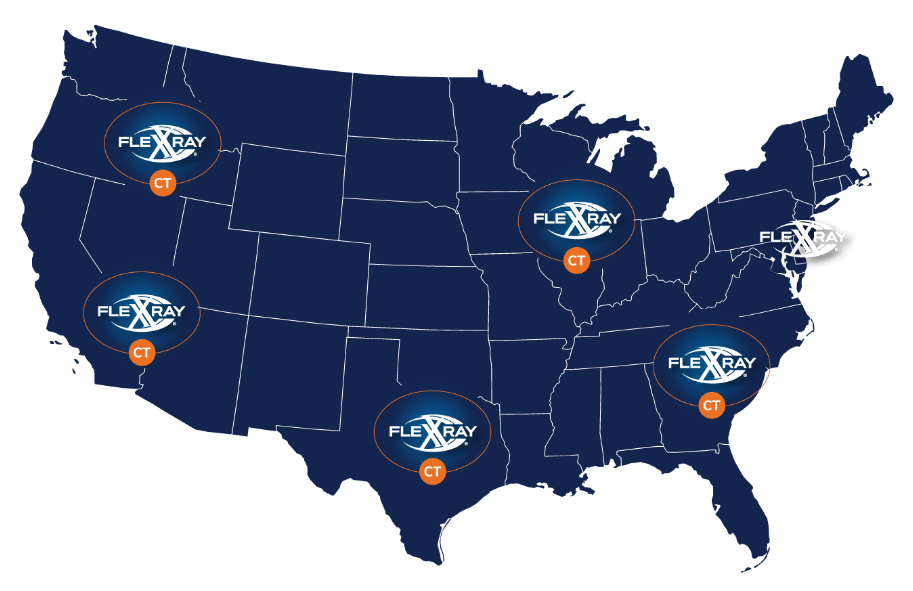

CT Inspection Across the U.S.

FlexXray’s CT capabilities aren’t limited to a single facility. We’re bringing advanced detection closer to you. Customers near our Texas, South Carolina, Nevada, Illinois, and Boise facilities can now access CT scanning to run sample tests on their products to validate product integrity and detect foreign material.

“We’re committed to staying at the forefront of food safety. By being the only third-party inspection provider to offer CT scanning across our facilities, we’re providing food manufacturers with the most advanced detection capabilities available.”

– Kurt Westmoreland, Chief Commercial Officer, FlexXray

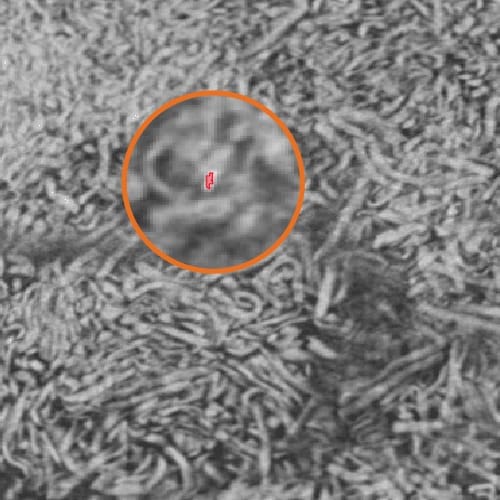

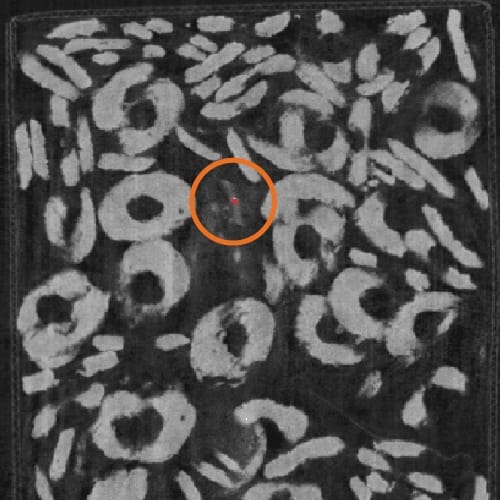

Product: Shredded Cheese

Contaminant: 0.3mm diameter sifter screen wire at 4mm in length

X-ray Inspection

CT Inspection

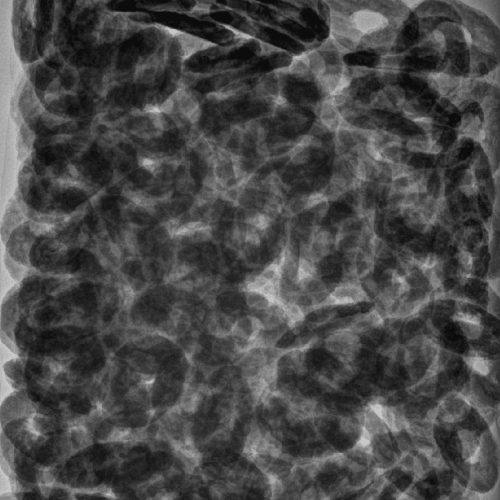

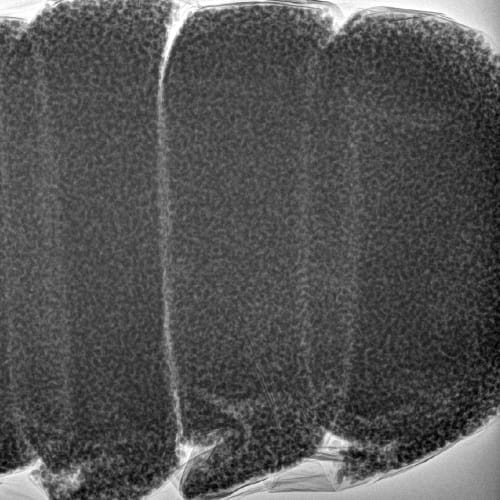

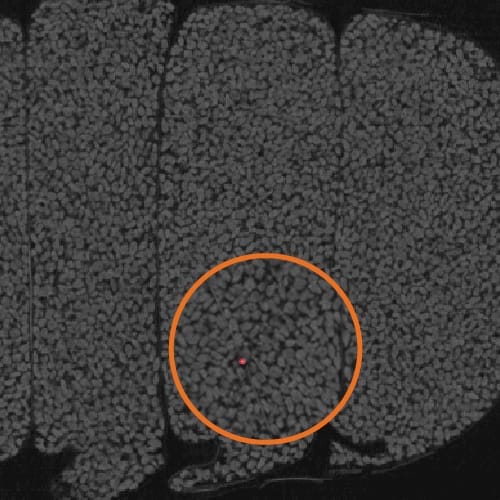

Product: Processed Chicken Rings

Contaminant: 2mm stone from chicken gizzards

X-ray Inspection

CT Inspection

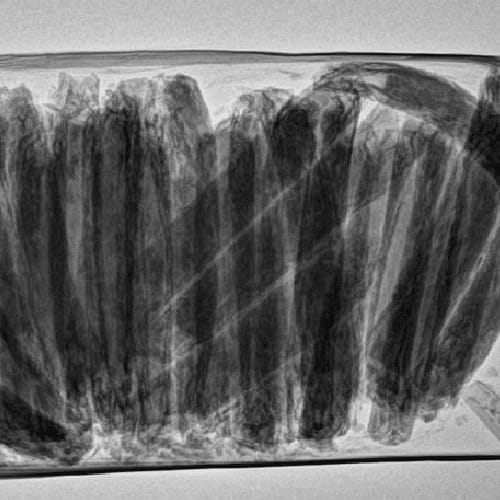

Product: Pet Food

Contaminant: 3mm aluminum

X-ray Inspection

CT Inspection

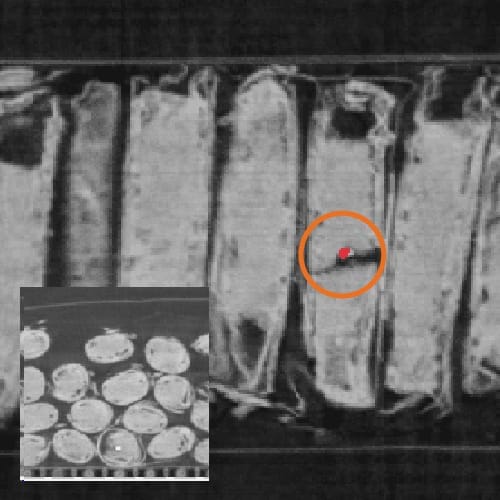

Product: Frozen Taquitos

Contaminant: 3mm rubber gasket from customer

X-ray Inspection

CT Inspection